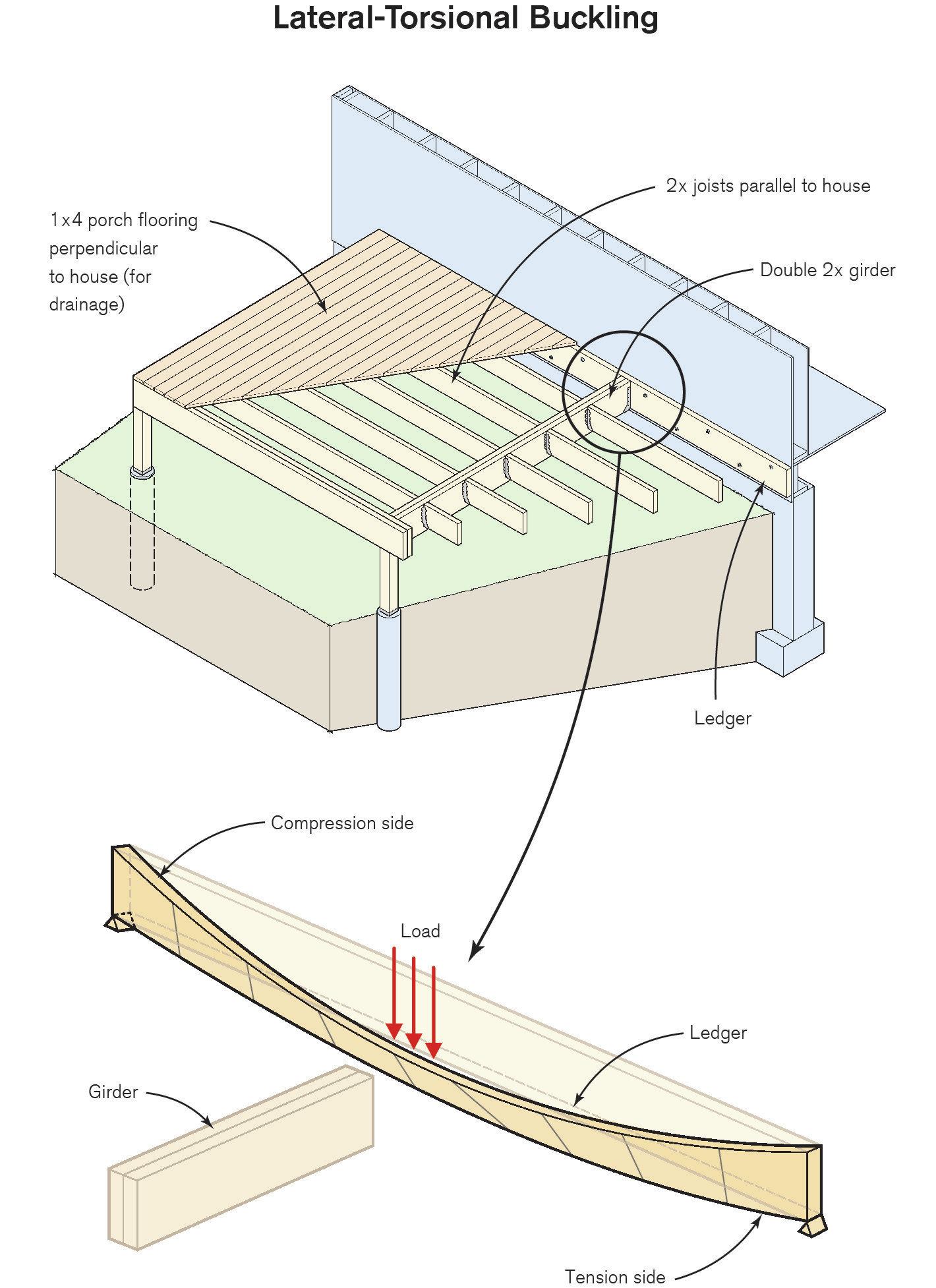

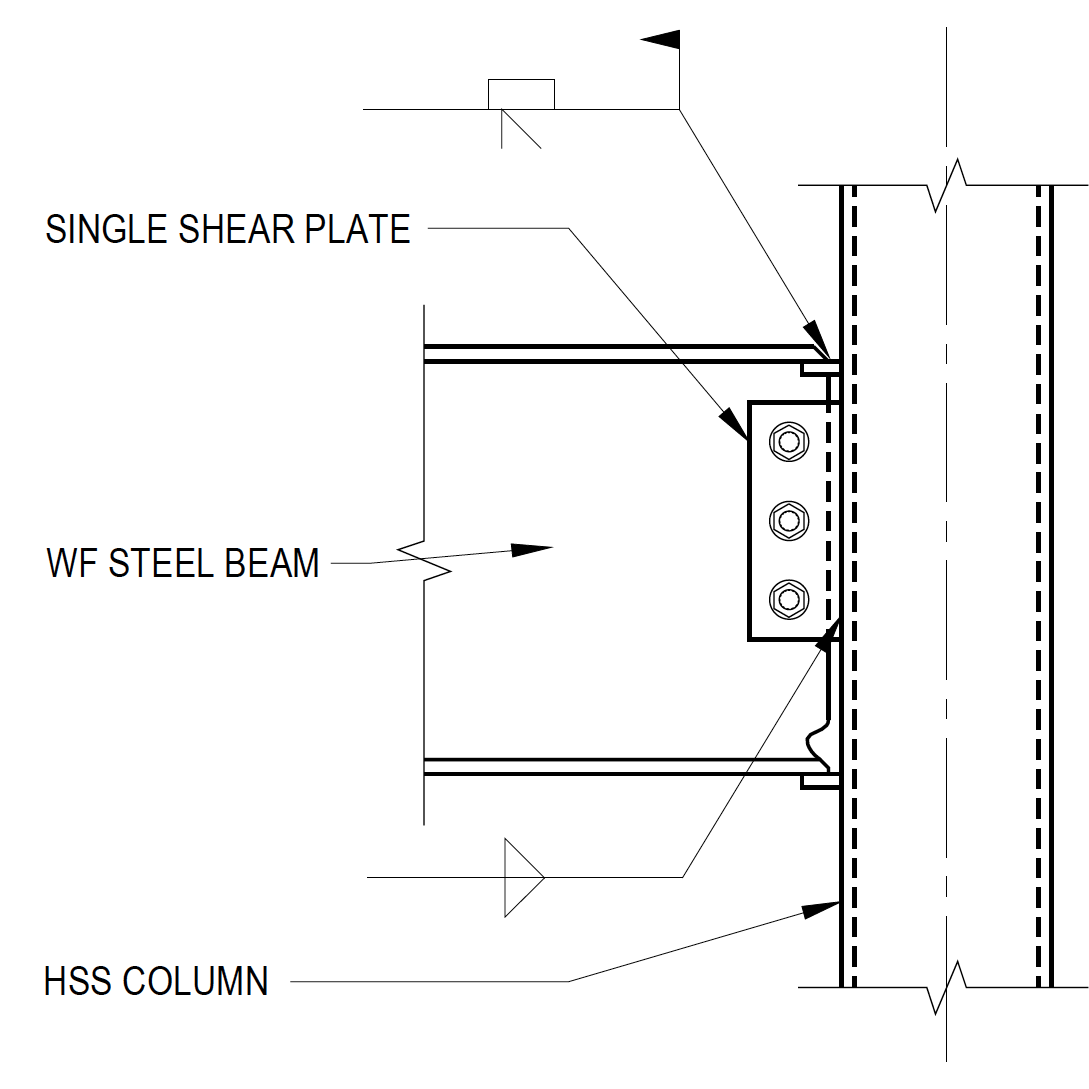

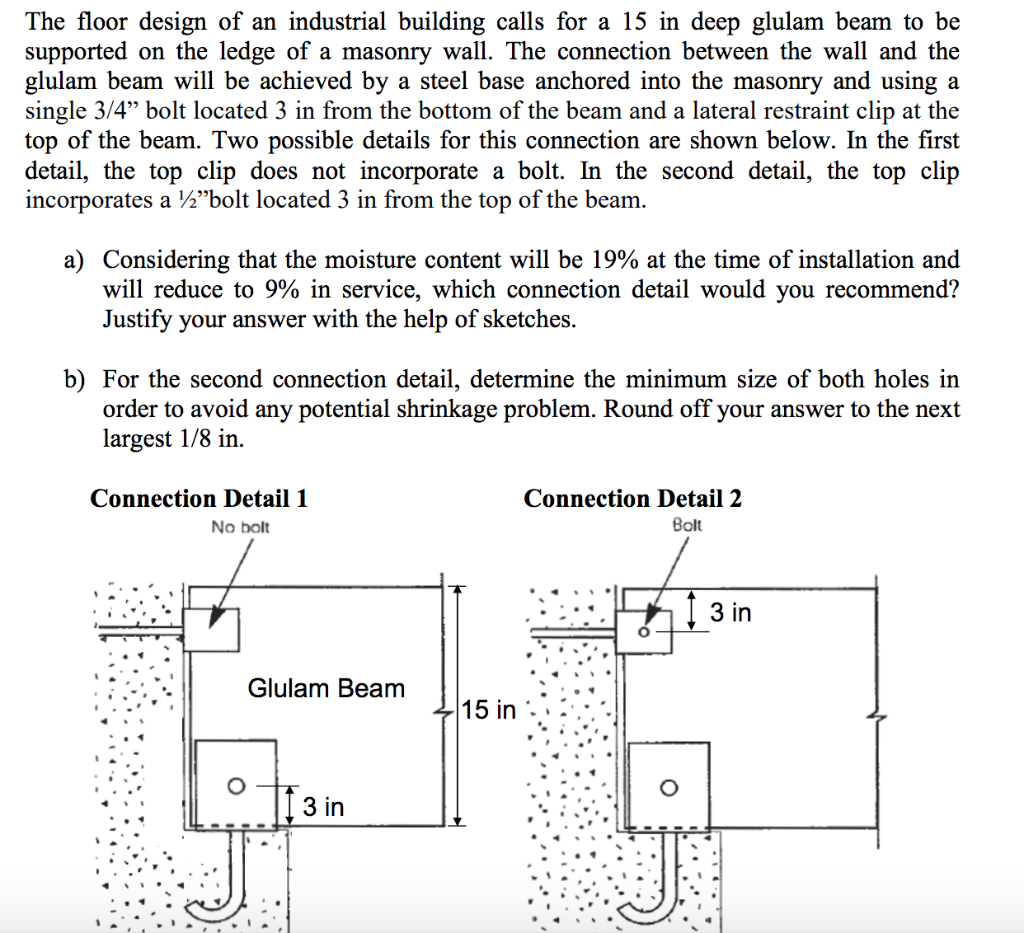

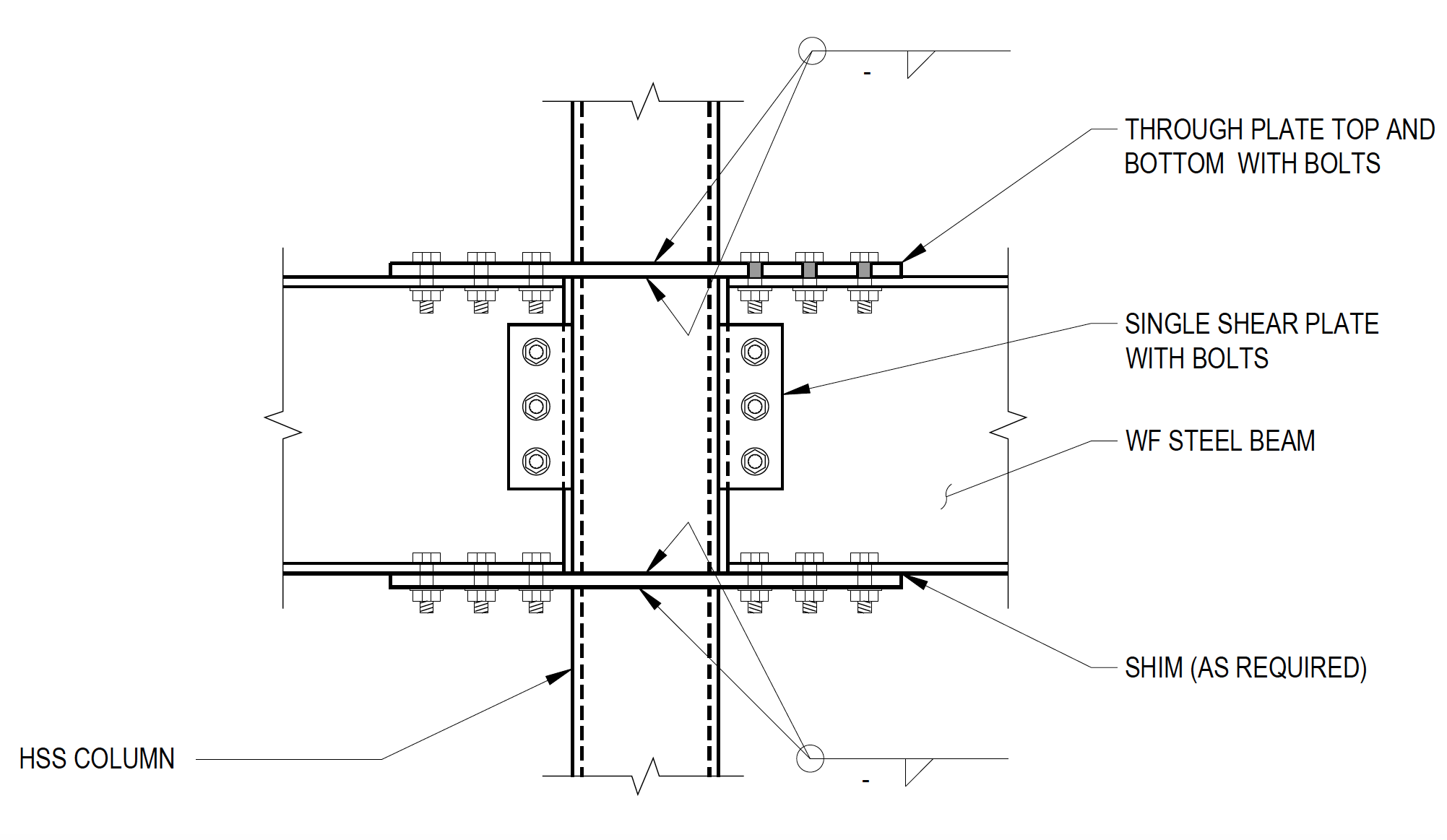

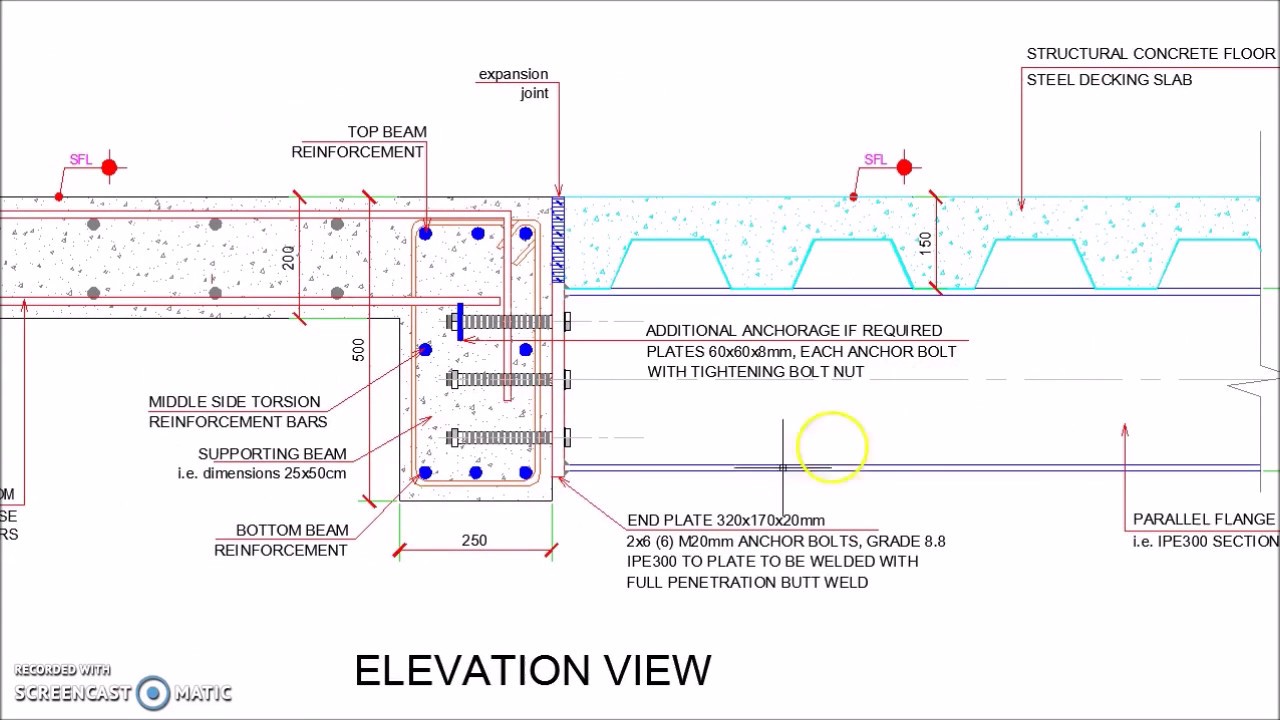

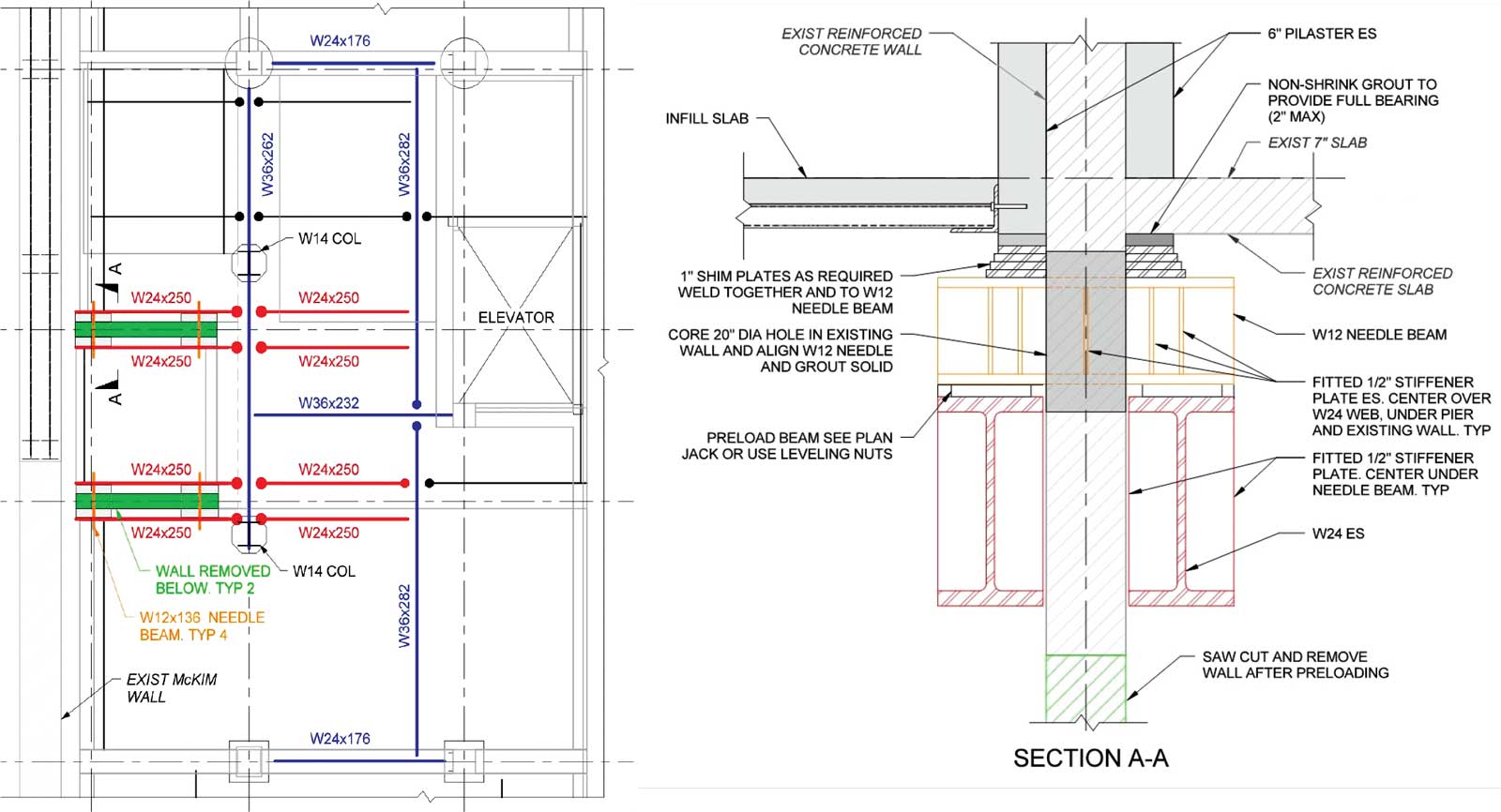

The lateral stability of a dropped beam such as the one below is dependant on the size of the opening, beam size and pony wall height Figure 5 Pony wall on top of garage door header Our TJ9000 specifiers guide provides guidance how to construct the pony wall and header based on the beam type, size and opening widthSteel Connections Dr Seshu Adluri Beam to Column Rigid Joints Stiffener plates are used to 'shore up' the column flanges against the forces transmitted by the beam flanges The stiffeners may be full length or may extend only part of the column web depthIn framed connections, an angle shelf is sometimes used to support the connecting beam during the erection, simply to facilitate the process (as shown below fig no1), though the angle shelf is not an integral part of the connection and may be removed after the connection process is over 3

Figure 4 8 4 Masonry Setback Wall Roof Connection Steel Frame Membrane Roof Masonry Roof

Steel beam connection to brick wall

Steel beam connection to brick wall-For wall, floor and roof construction Nail laminated timber, another form of mass timber construction, has been utilized for over years It includes vertical 2x bolts were utilized for glulam beamtobeam connections This chart shows 10 nails, all referred to as 10d, and each with potentially different performance characteristics Thus,In this article you find the seven most used beam connections, prepared for welding and/or fastening But it also provides a clear insight into unlimited possibilities for H beam coping Example 1 Left a bolted beam to beam connection, sloped shear tab connection with notches and an intermediate

Self Centering Steel Timber Hybrid Shear Wall With Slip Friction Dampers Theoretical Analysis And Experimental Investigation Cui The Structural Design Of Tall And Special Buildings Wiley Online Library

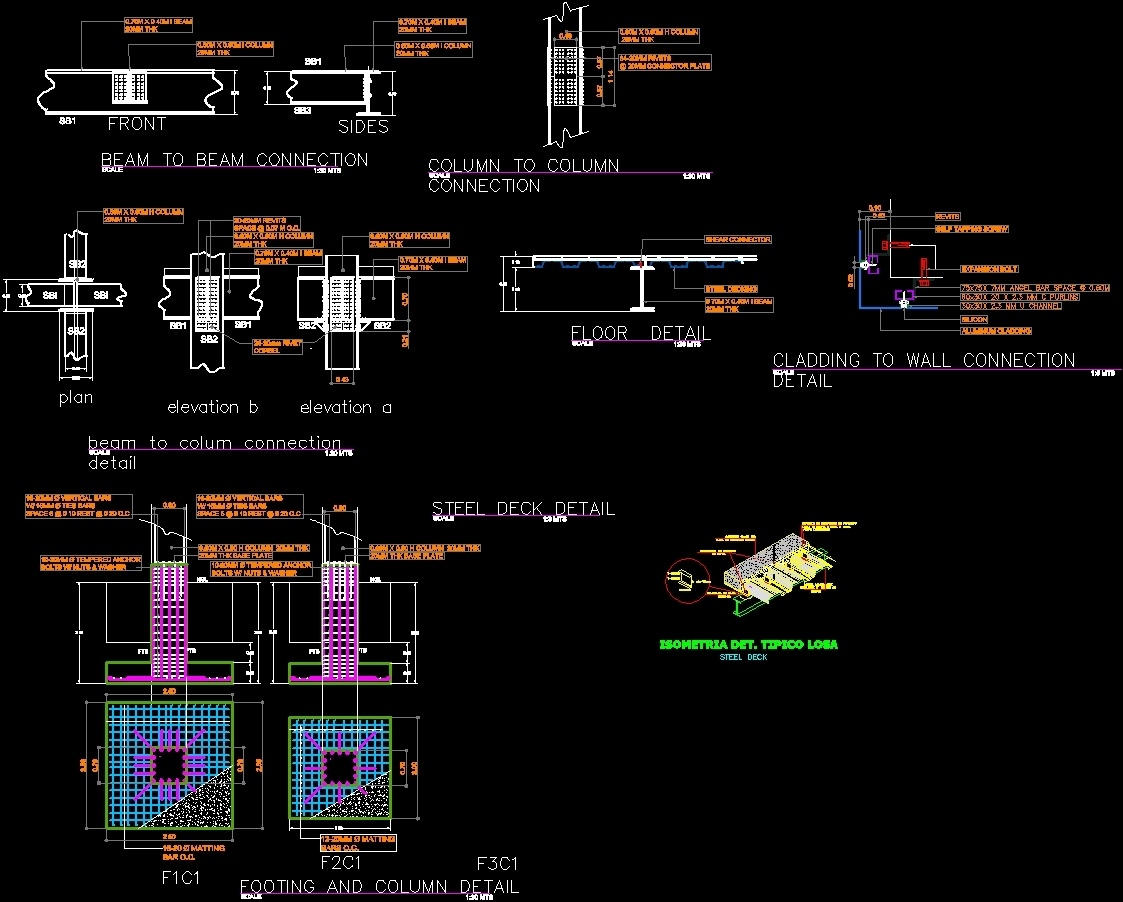

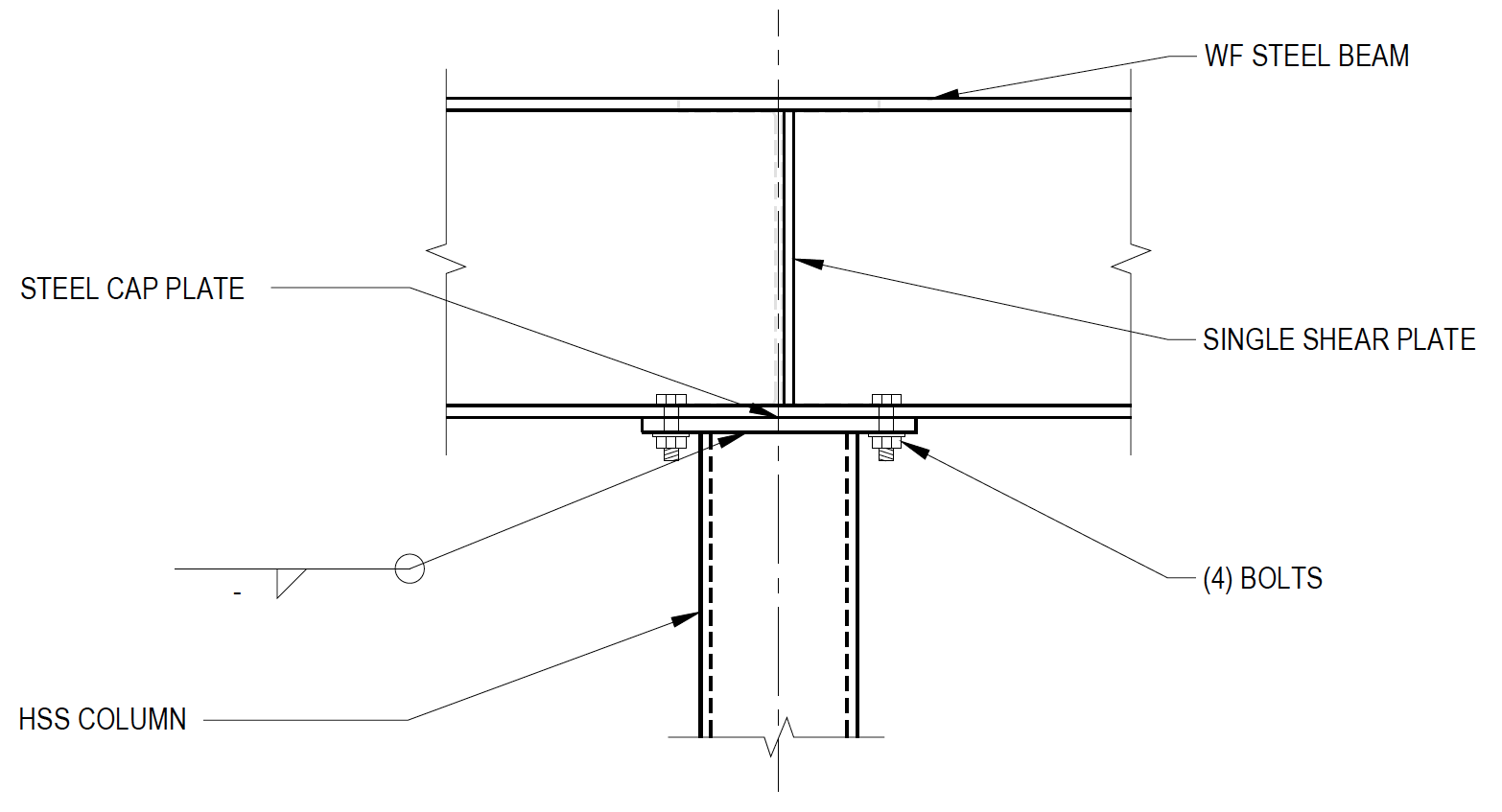

Let me explain the situation, I have a wall and I want to insert a beam into that wall I have no problem drawing the beam, but the wall is not cutted, I mean, its volume remains equal as if the beam were not there, it is like the wall and the beam are both in the same space So I need, when I insert the beam, the wall volume to be modifiedTB217 provides guidelines regarding the percentage of the beam width that must be supported (75%) and the beam bearing capacity for various beams, pile diameters, and bearing widths The transfer of uplift and lateral loads from the beam to pile is often accomplished by means of bolted connections A common detail incorporates two 5/8Become VIP Member There are various types of steel beam connections used in structures Steel beam connections are categorized into two groups namely framed and seated connections In the framed steel beam connections, the beam is connected to the supporting steel element through fittings whereas in case of seated connections, the beam is positioned on seat similar to the case where beam is placed on masonry walls

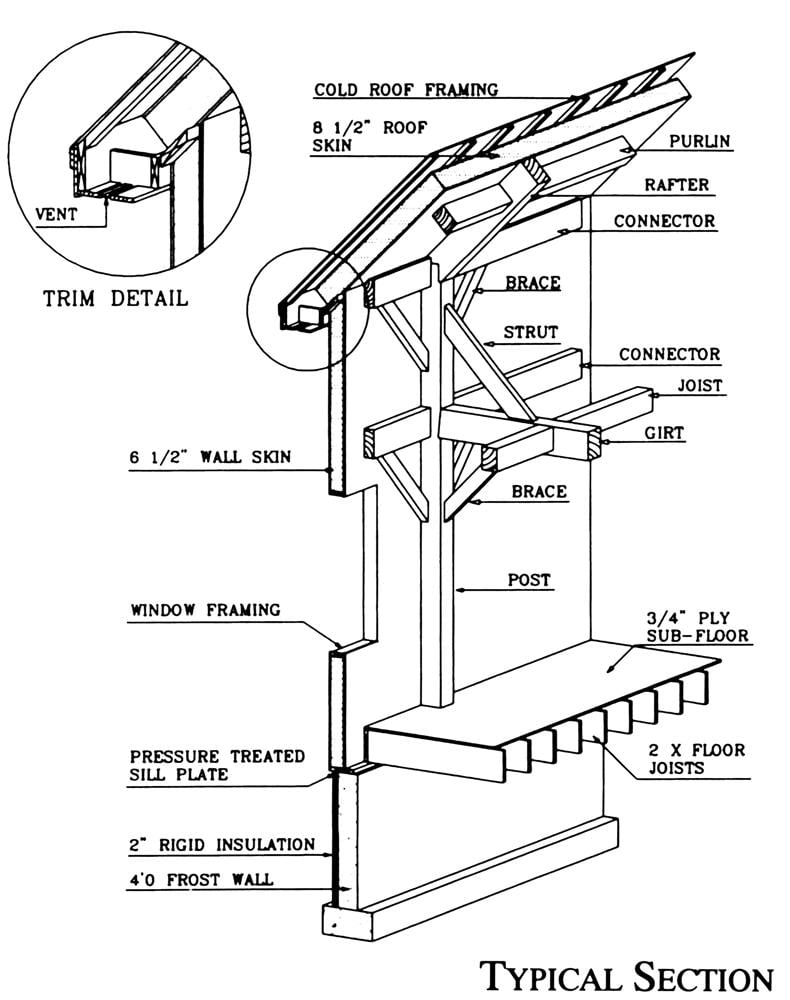

H is the height of the wall and α is one of the coefficients of the differential equation set up in the shear connection solution α includes axial and bending stiffness of the columns and shear and bending stiffness of the beams and appears to be a useful parameter for comparing the stiffnesses of different wall shapesFor a concrete wall, I set the Ibeams 4 to 5 feet apart If the wall is block or stone, 3 to 4 feet apart is a safer bet In any case, I position the beams so that they can extend up into a joist bay steel or wood blocks spanning the joists will hold the Ibeams tight to the wallIn order to attach the floor joists correctly, you will need to improvise and attach a ledger board to the wall Secure it to the wall using nails and 4inch lag bolts They should be driven into the wall studs supporting the wall Once the ledger board is secure, attach joist hangers and fasten them to the ledger board

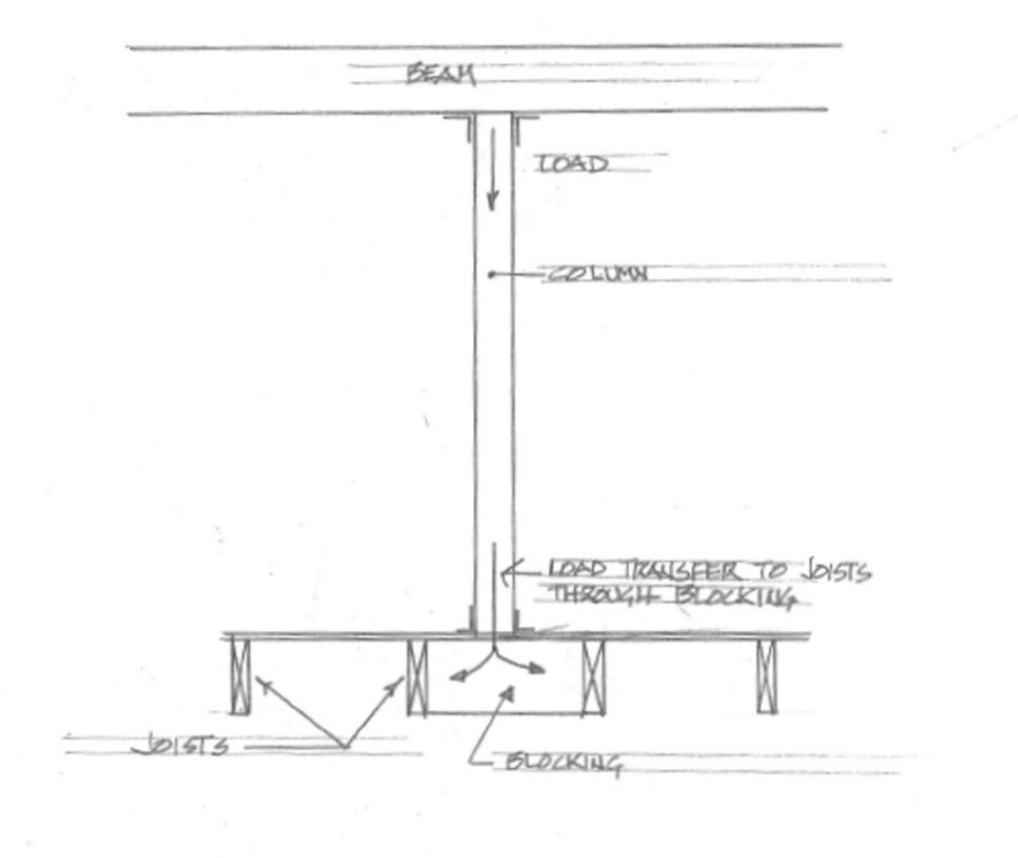

E steel beam connections to concrete core walls e steel beam connections to concrete columns, e steel beam connections to masonry walls and beams Connection details should recognise the physical characteristics of both steelwork and the material to which the steelwork is connected Details shouldIn the simplest usage, an Ibeam rests in pockets cast in foundation walls, with floor joists on top of it More often, though, wood is bolted to the web;Steel beam members can span up to 18m, but the most usual range of steel beam spans rang from 3m to 9m While steel beams are erected, column to beam connection and beam to beam connections are encountered There are different types of column to beam connection which are selected based on the type of loads imposed on the column to beam joint

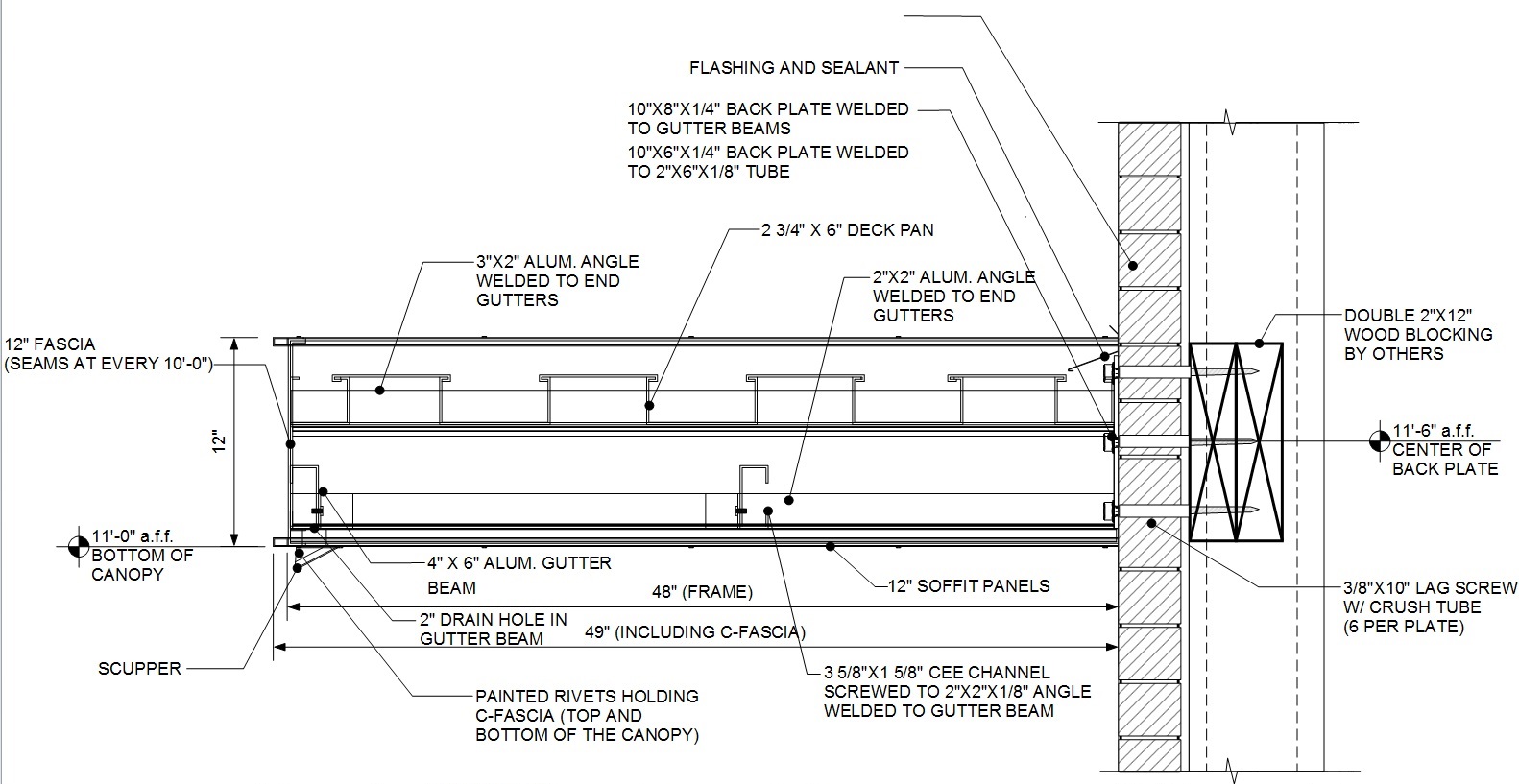

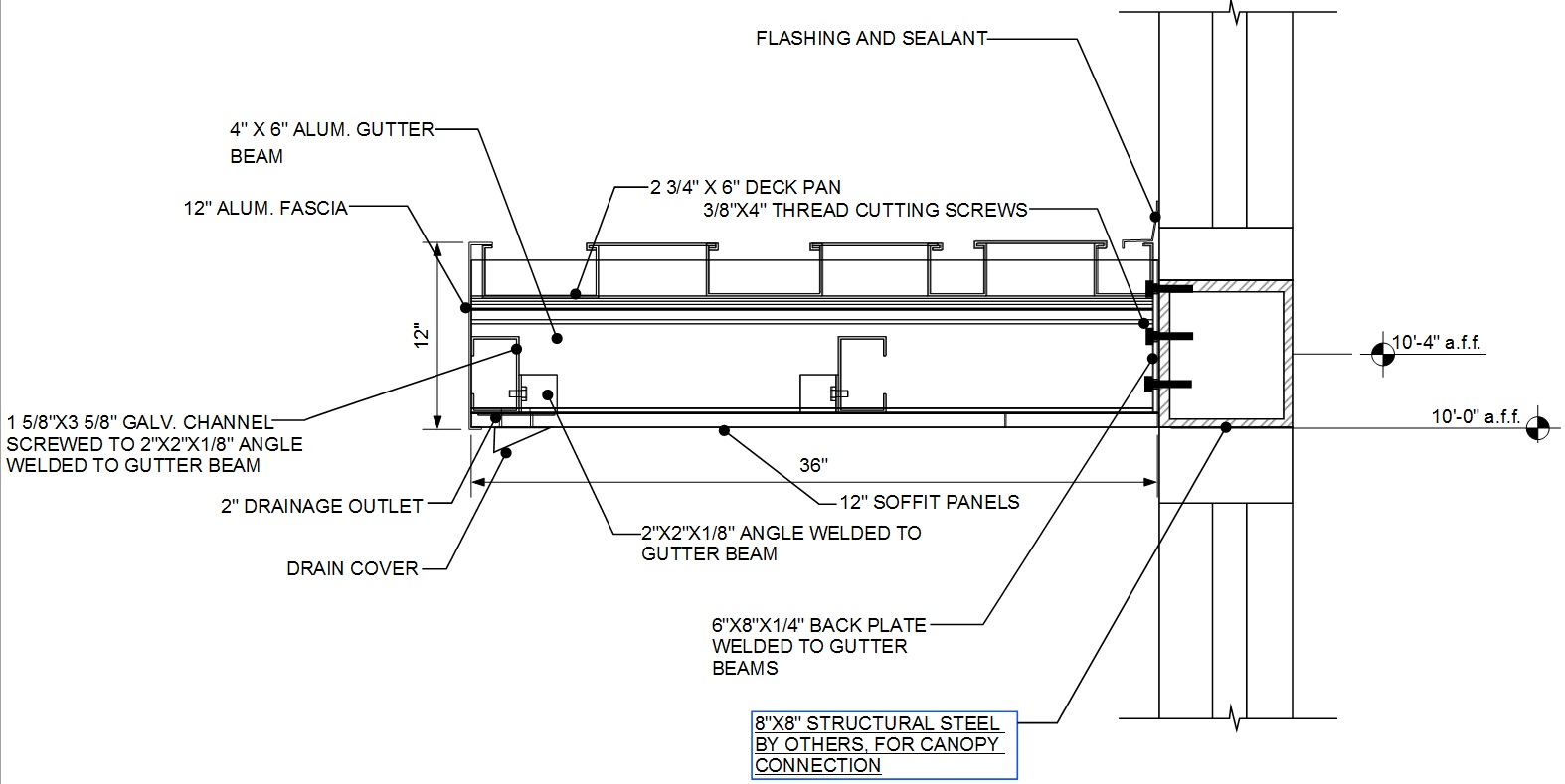

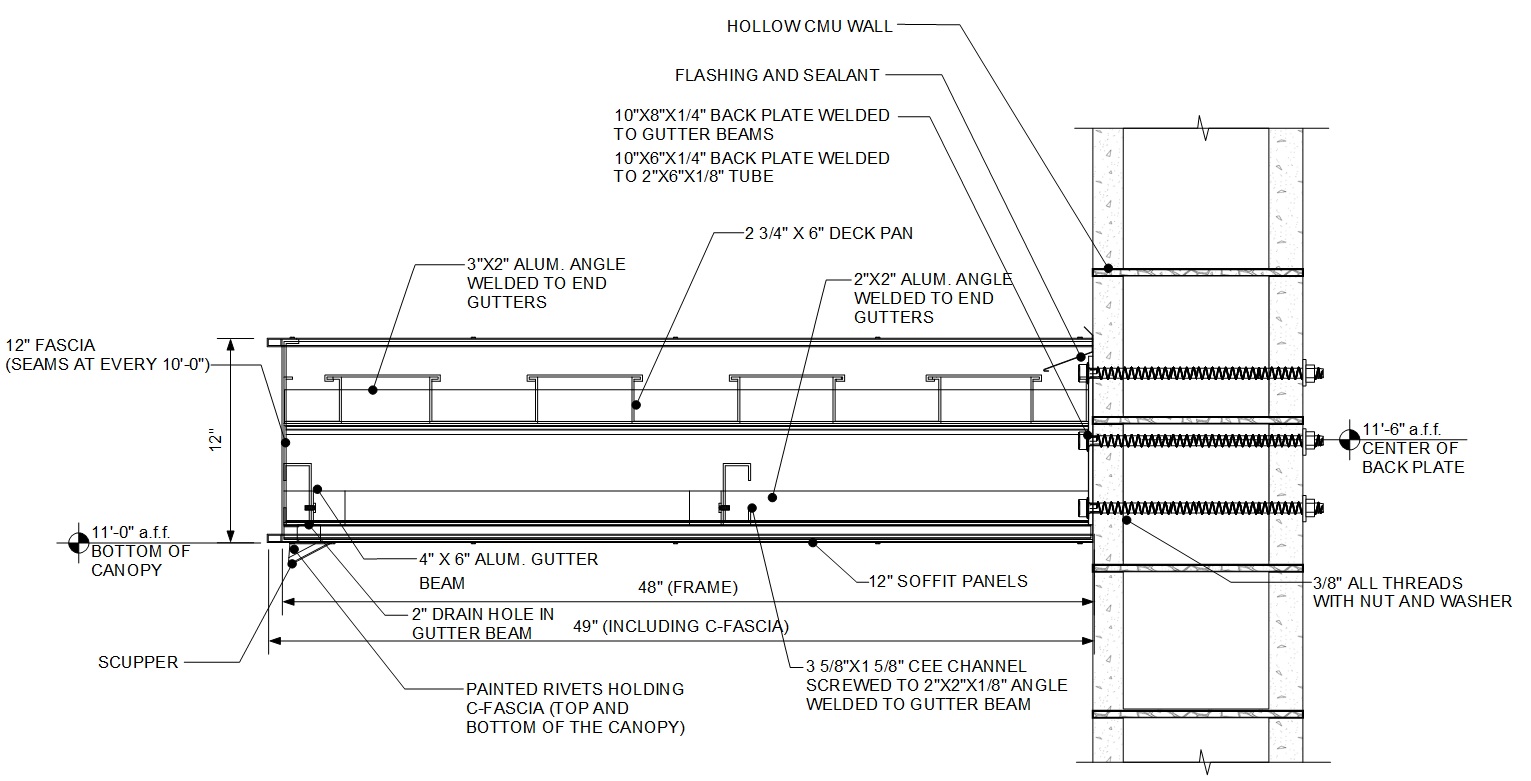

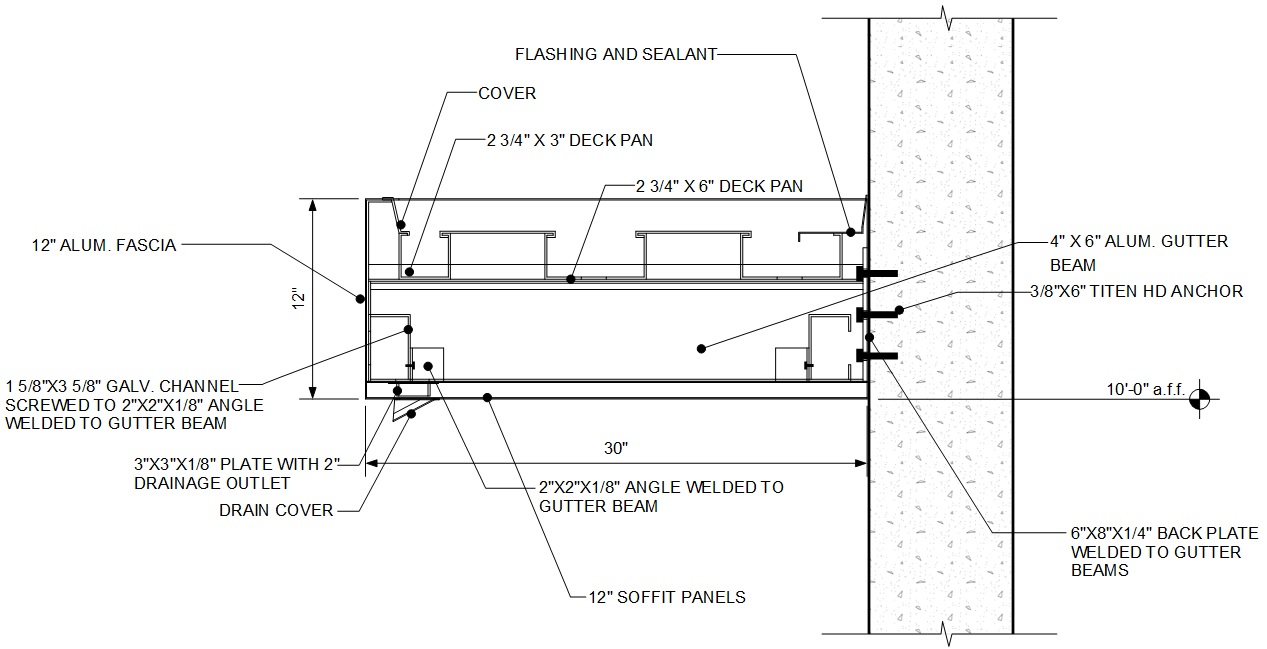

Connection Details Aluminum Canopies Architectural Fabrication

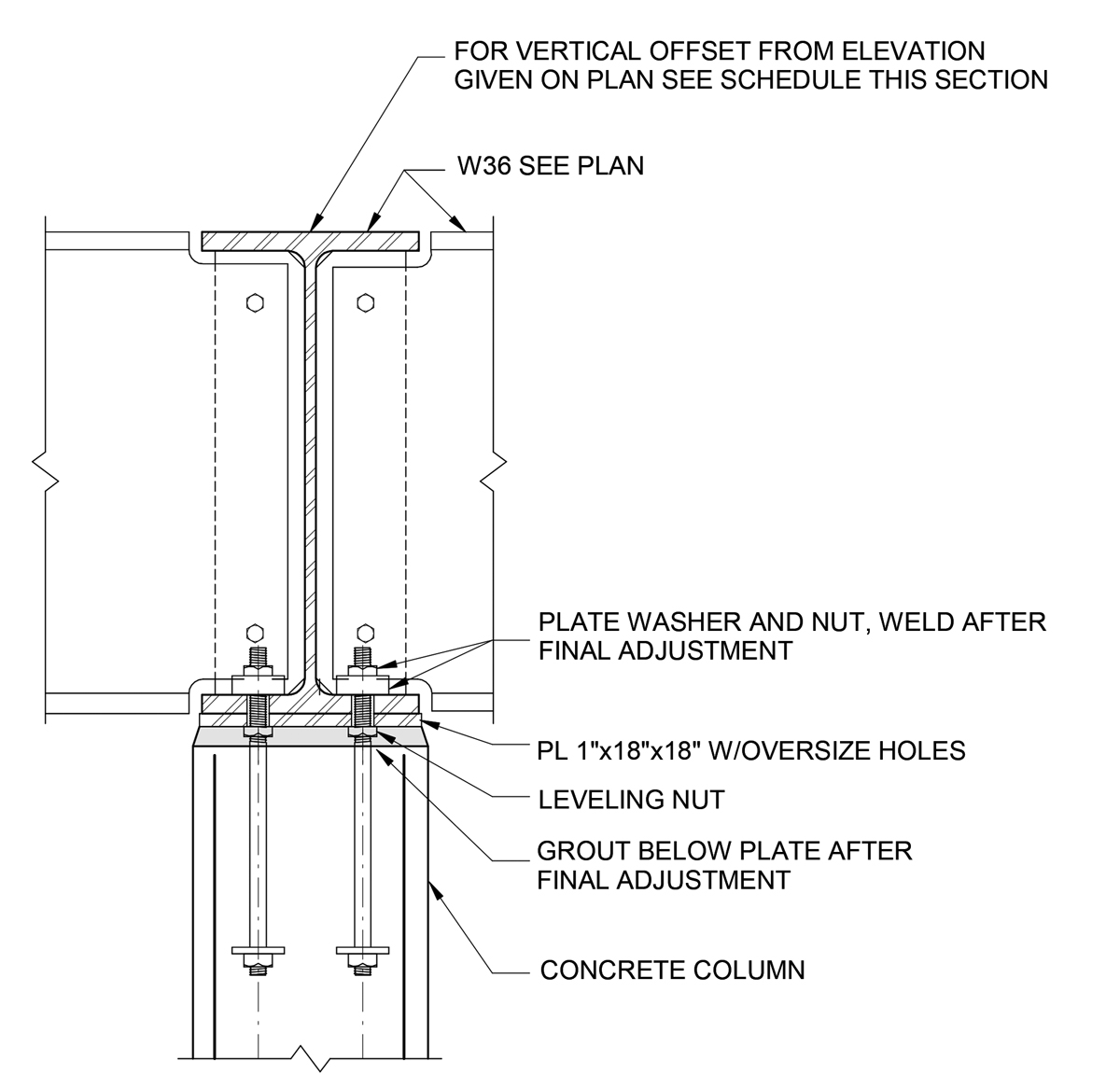

Steel Beam To Concrete Wall Connection Design Example Lewisburg District Umc

In general, all beam connections are classified as either framed or seated In the framed type, the beam is connected to the supporting member with fittings (short angles are common) attached to the beam web With seated connections, the ends of the beam rest on a ledge or seat, in much the same manner as if the beam rested on a wallIn general, all beam connections are classified as either framed or seated In the framed type, the beam is connected to the supporting member with fittings (short angles are common) attached to the beam web With seated connections, the ends of the beam rest on a ledge or seat, in much the same manner as if the beam rested on a wallHow to Wall Under an IBeam An Ibeam has three distinguishable parts a vertical web and two horizontal flanges, one at the top and one at the bottom When the floor joist span exceeds the

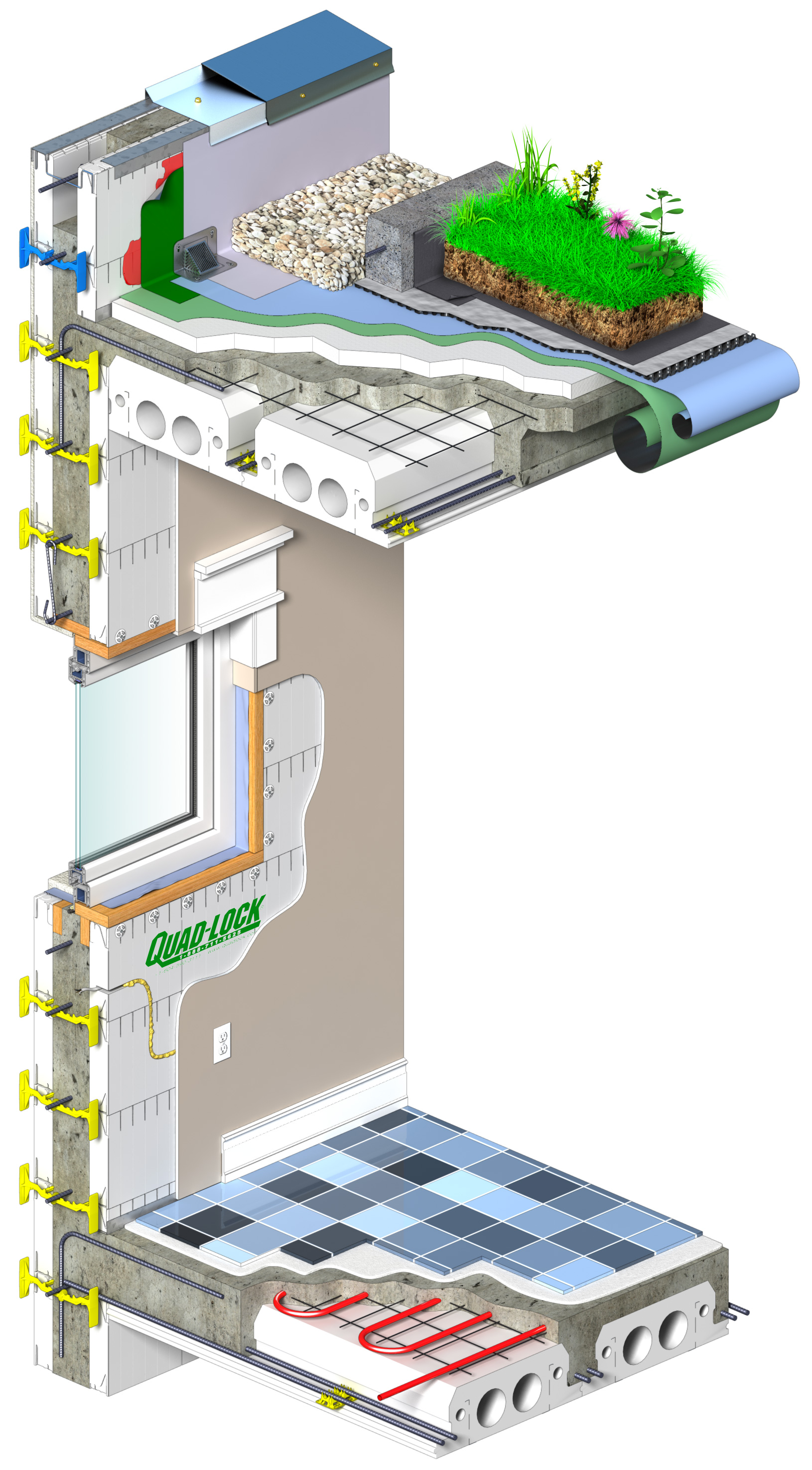

Insulated Concrete Forms Icf Technical Library

Priority Based Connection Methods In Archicad Youtube

17/16 in x 17/16 in x 23/4 in G185 18Gauge Framing Angle (1Pack) Angles, straps, and braces join and reinforce Angles, straps, and braces join and reinforce joints with simple, multipurpose solutions Available in many lengths, widths, and gauges, they provide a tension connection between 2 wood membersThe beam is 5" wide and 8" tall I'm considering constructing a 2x4, nonload bearing wall directly under the beam but I'm not sure how to attach the 2x4 framing to the underside of the beam Here's a picture of the beam How can I attach a 2x4 wall frame to the underside of a steel IbeamThere was a typo he meant that the 'wall' beam was to be either 250UB or PFC, supported either by 3 of 90x45 or by the 75x75x4SHS This makes a bunch more sense I'll support the 250UB with the SHS with welded connections and I'll have to pull the plaster off before deciding on the connections for the bifold door beam

Solved Connection Of Steel Beam To Shear Wall Autodesk Community Robot Structural Analysis Products

Connecting Girders To Deck Ledgers Jlc Online

The preferred method of installing and attaching a steel beam to a concrete wall is as follows When the concrete is poured, 2 anchor bolts are embedded into the concrete inside the beam pocketThis design is adjustable and mounts flush underneath the building's IBeam's flange Use the BC24SERIES hook style beam clamp to provide a load rated overhead rigging point from structural IBeams with widths ranging from 2″ and 6″, 6″ and 9″ or 9″ and 12″02 1 0226 Steel Beam Connection To Concrete Masonry Wall Warehouse Masonry To Steel Beam Anchor Structural Ering General Discussion Eng Steel Beam Connection Detail On Top Of Masonry Stone Or Brick Load Bearing Wall Steel Beam To Rc Wall Connection 2 Concrete Walls Reinforced Transpa Png Pngkey

Revit Structural Connections Autodesk Community Revit Products

Steel Beam Reinforced Concrete Wall Simple Connection

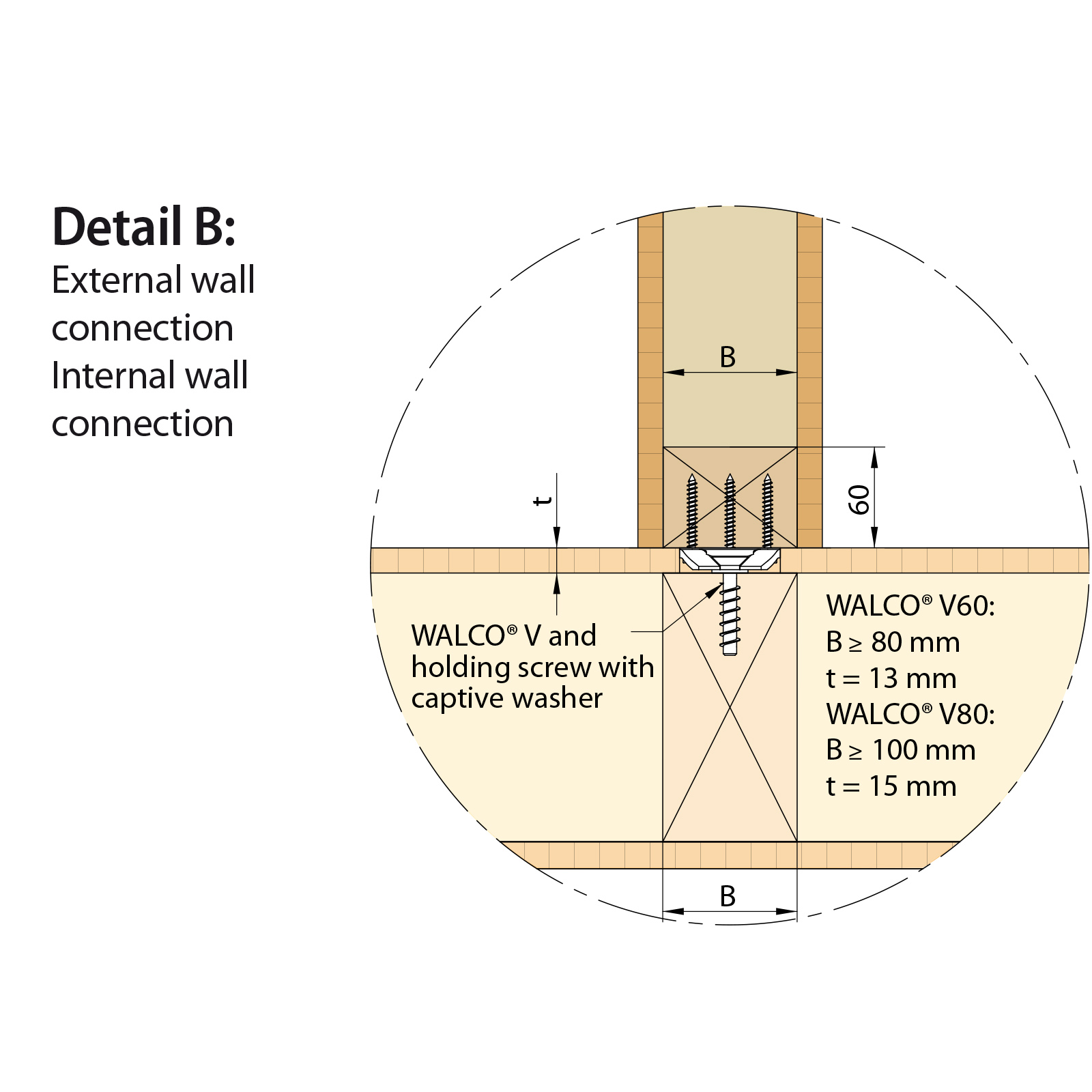

When you want to attach wood to a steel Ibeam, there are two acceptable ways to do it The first and most traditional way is to pack the web between the Ibeam flanges with multiple pieces of wood, then bolt them together This is a very strong connection, but it wastes a lot of time and raw materials in the processBeam to Wall Connections What's easier than setting the beam on something?This will mean removing locally wall plate and taking off 1 or 2 layers of brick My question is how do we fix this beam to masonry so it doesn't rotate I have looked in Simpson catalogue and the only connection that would be suitable is the wall strap (please see attached) The problem is that this only works for new masonry wall

Attaching Non Load Bearing Walls To Steel I Beams Home Improvement Stack Exchange

Seismic Design Of Hybrid Coupled Wall Systems State Of The Art Journal Of Structural Engineering Vol 136 No 7

CAD Details LP offers downloadable information for your building projects Find the information you need by downloading BIM content, architectural specs and CAD Installation Detail filesFor a concrete wall, I set the Ibeams 4 to 5 feet apart If the wall is block or stone, 3 to 4 feet apart is a safer bet In any case, I position the beams so that they can extend up into a joist bay steel or wood blocks spanning the joists will hold the Ibeams tight to the wallThe connection between the beam () and the column is realized through 2 already prepared and welded horizontal plates to the end of the upper and the lower part of the beam that are additionally strengthened with 2 vertical websThe dimensions of the joints are same as the ones in the SP4 model, however in this model are used exterior

Structure Steel To Concr Home Building In Vancouver

Wide Flange Beam To Hss Column Moment Connections Steel Tube Institute

PINNED CONNECTIONS In contrast to roller supports, a designer can often utilize pinned connections in a structural system These are the typical connection found in almost all trusses of the type of support condition on the deflection behavior and on the location of maximum bending stresses of a beam supported at its ends19 "The Do's and Don'ts of Foundation Beam Installation" Special Thank You To – Southeastern Wisconsin Municipal Building InspectorsSoutheastern Wisconsin Municipal Building Inspectors – Wisconsin Association of Foundation Repair Professionals (WAFRP) Pictures Courtesy of • John Voight, ry Basement Systems of Milwaukee • James Jendusa, Jendusa Design & EngineeringThe beam is 5" wide and 8" tall I'm considering constructing a 2x4, nonload bearing wall directly under the beam but I'm not sure how to attach the 2x4 framing to the underside of the beam Here's a picture of the beam How can I attach a 2x4 wall frame to the underside of a steel Ibeam

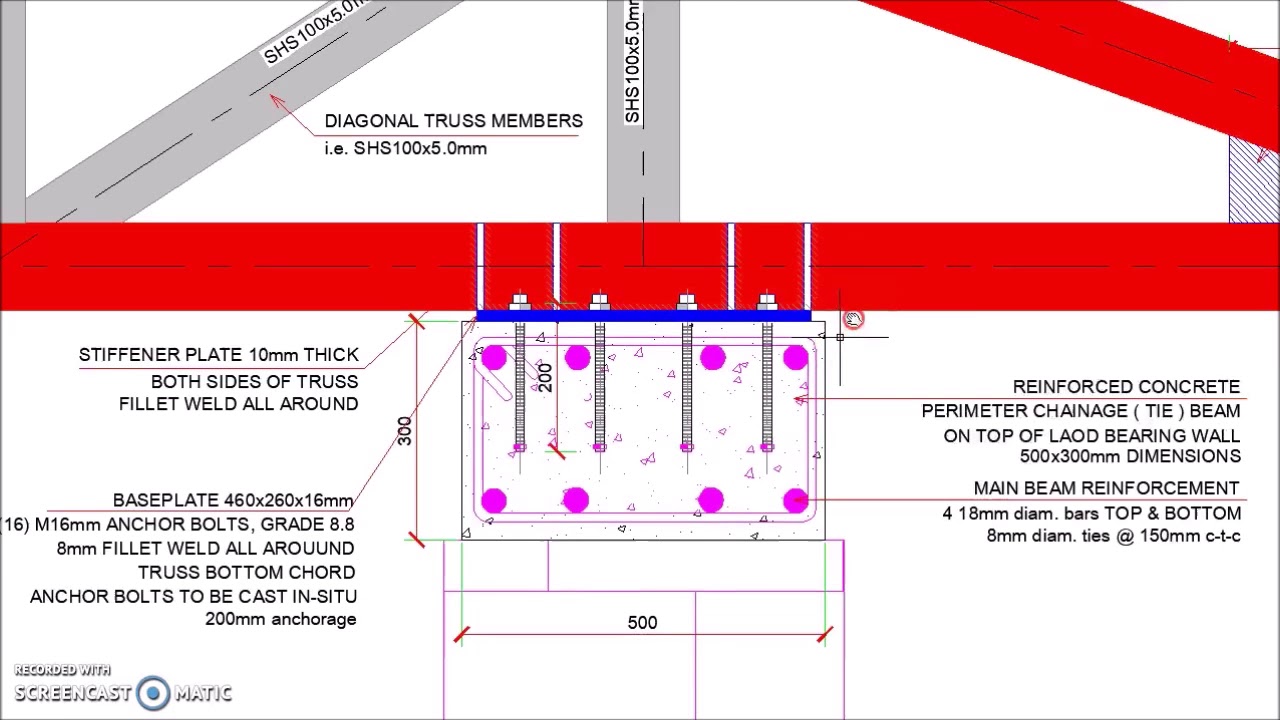

Roof Steel Truss Supported On Masonry Wall With Concrete Chainage Beam Youtube

A Uniform Horizontal Beam Of Length L And Mass M Is Attached To A Wall By A Pin Connection Youtube

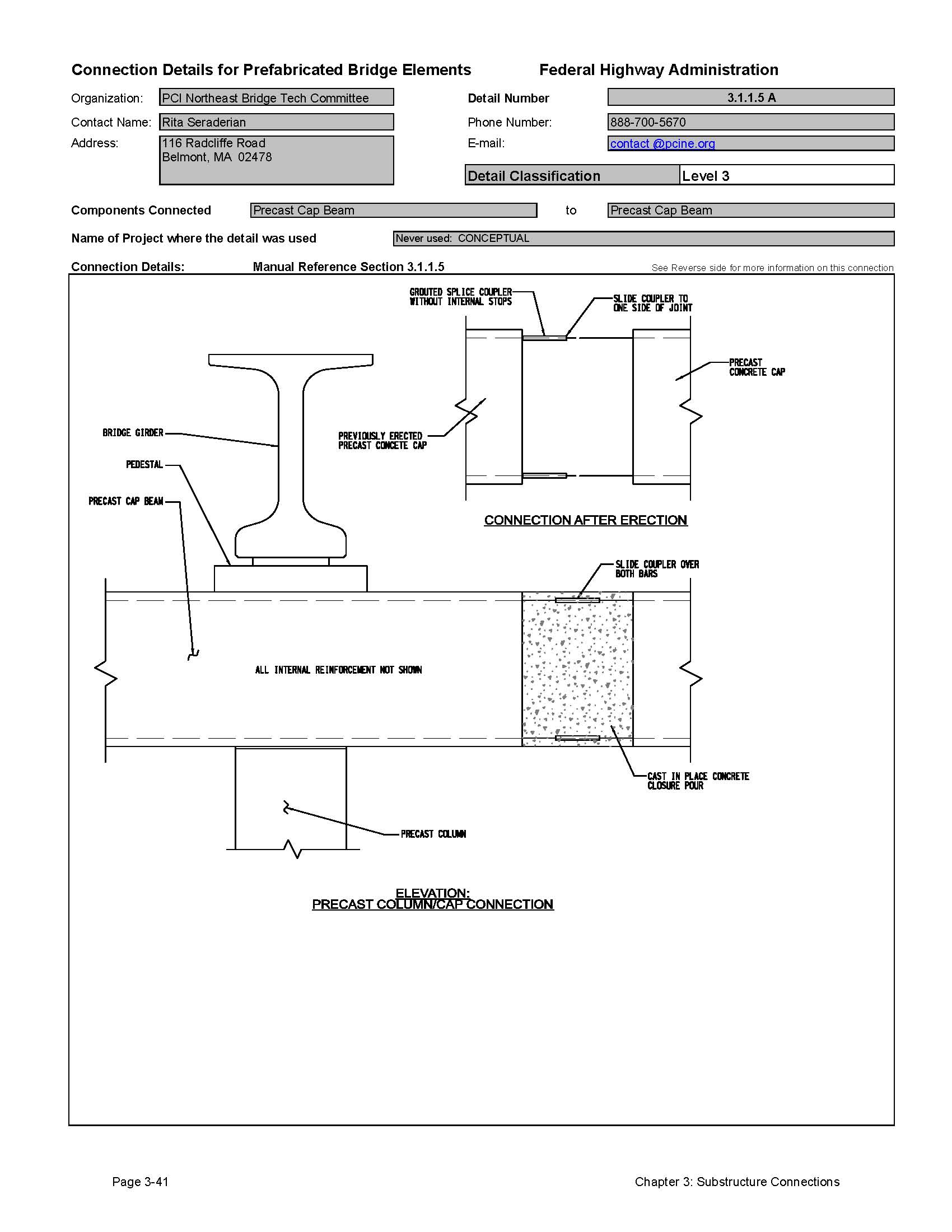

If you want to model the wall using a frame/column element, then draw your beam to the point where you want to connect at the outside of the wall, a point which would be disconnected from the column half the width of the wall Attach beam end point to the column by selecting beam end joint and column joint, then assign a joint constraint (Body4 Types Of Precast Connections (1) beamtoslab connections (2) beamtocolumn connections (3) walltoframe connections (4)column splices, including to foundations The four rules for satisfactory joint design are that (1) The components can resist ultimate design loads in a ductile mannerIt was my impression that in a ridge beam roof, the rafters are sort of hanging off the fullysupported beam Yes, but in this cast the end rafters bolted to the studs would be spreading the load of the beam and the rest of the roof across many studs IOW those two rafters would be acting like an AFrame/Header supporting the beam

Masonry Concrete To Timber Timber Frame Hq

Prefab Walls Knapp Connectors

From https//bayarearetrofitcom Retrofitting post to beam connections is expensive and a complete waste of money The building code says so, common senseWhen a beam spans two party walls, a splice is also recommended to easily install the beam, with the alternative being temporarily removing a large wall section As a rule of thumb, the flange plates need to be at least the same thickness as the beam's flange, and the same rule applies to the web platesThe steel Ibeams most often seen on job sites are called W (wide) and S (standard) shapes, depending on the width of the flange Steel beams are designated by shape, depth, and weight For example, a W8x35 beam is a Wshape about 8 in deep and weighing 35 lb per lin ft

Connection Details Aluminum Canopies Architectural Fabrication

How To Pocket Joist Into Double Wythe Solid Brick Wall Home Improvement Stack Exchange

The preferred method of installing and attaching a steel beam to a concrete wall is as follows When the concrete is poured, 2 anchor bolts are embedded into the concrete inside the beam pocketConcealed connection systems rely on embedding the connectors, whether wood tenons or metal plates, within the thickness of the posts or beams While mortise and tenon joints were originally fashioned onsite in traditional post and beam construction, stock connectors are now availableFire Wall Hanger The patentpending DGBF is a topflange hanger designed to connect wood beams to wood stud walls The hanger features a beam bumper that reserves space for the drywall to be installed after framing

Wide Flange Beams In Light Frame Construction Simpson Strong Tie Structural Engineering Blog

Structure Steel To Concr Home Building In Vancouver

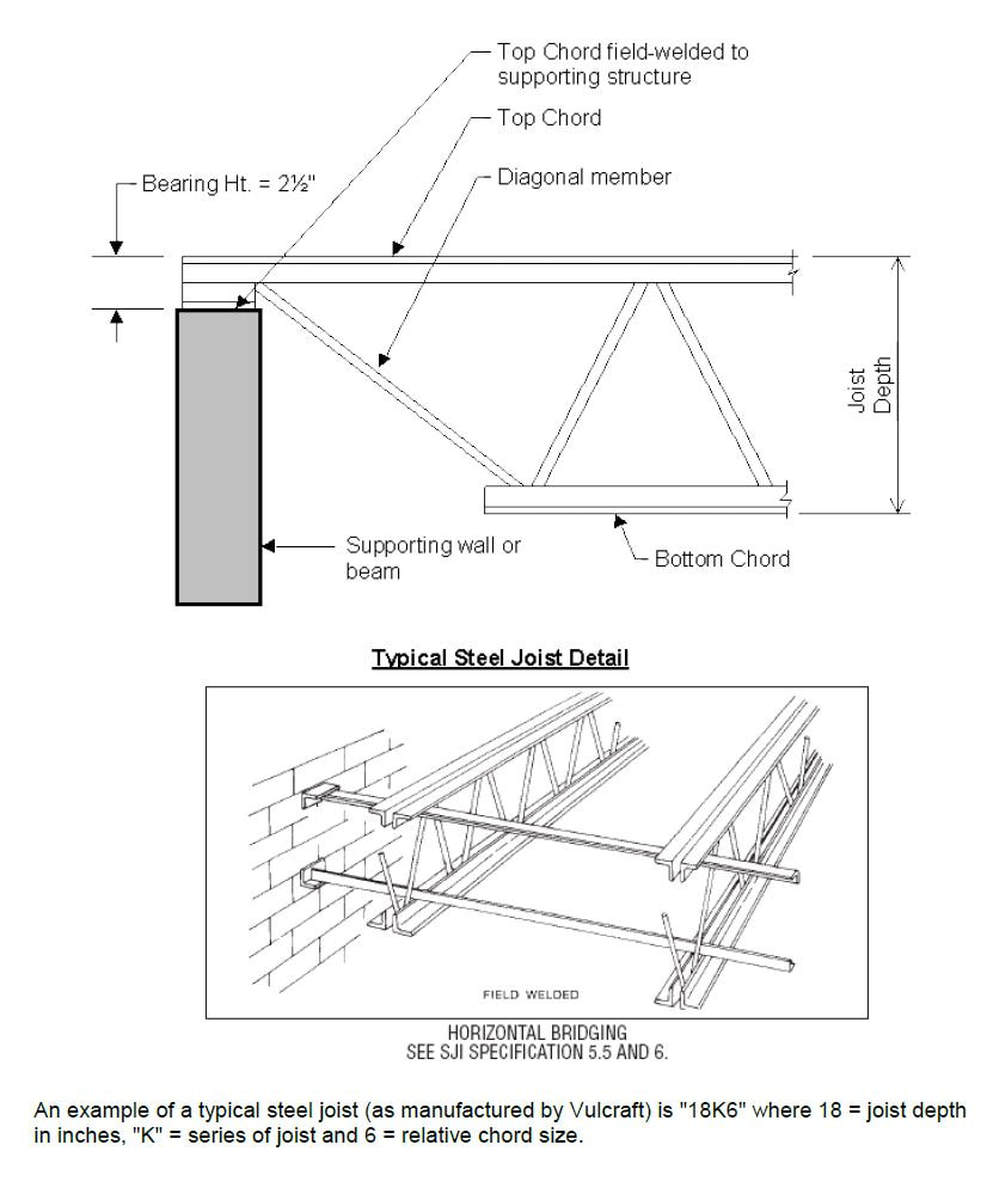

F4 Floor to Load Bearing Wall Connection F5 Floor Bearing on IBeam Connection F6 Lapped Joists F7 Continuous Joist F8 Floors to IBeam Side Connection F9 Joists Supported by Shallow IBeam F10 Joists Supported by Deep IBeam F11 Floor Joists at Interior Bearing Wall F12 Joists Bearing on Foundation at OpeningStronger post to beam connections jlc steel column and brackets a structure steel to wood home building how to repair a load bearing post diy ce center Structure Steel To Wood Home Building In Vancouver Structural Steel Custom Ii ManufacturingJoin a beam to a wall by sketching a beam and snapping one of its endpoints to the center of the wall Setback and cutback apply when connecting beams to structural walls The beams are independent of one another, are only associated with the common wall, and will cut back from the wall accordingly

02 1 0713 Floor Connection Detail Option 3 International Masonry Institute Construction Details Architecture Steel Architecture Steel Columns

Wide Flange Beams In Light Frame Construction Simpson Strong Tie Structural Engineering Blog

Qualward IBeam Heavy Bag Hanger, Heavy Duty Steel 315" W Beam Clamp Hook, Punching Bag Hanger for Boxing, Muay Thai & MMA Training in order to lift, rig, or support them for various applications They can be a handy way to connect parts and pieces in cases when drilling or welding the materials would damage or otherwise alter theirHanger Connection – When it is desired to maintain the continuity of the wall for structural, aesthetic, or construction reasons, a wall hanger can be used to suspend the roof or floor system Hangers are generally anchored to a wall through a joint and into a bond beamStrength Beyond Steel From testing to service to availability, everything we do is engineered to ensure your project's success With every product, you know you are getting the quality, value, service and ontime delivery that we have built our reputation on for the past 60 years

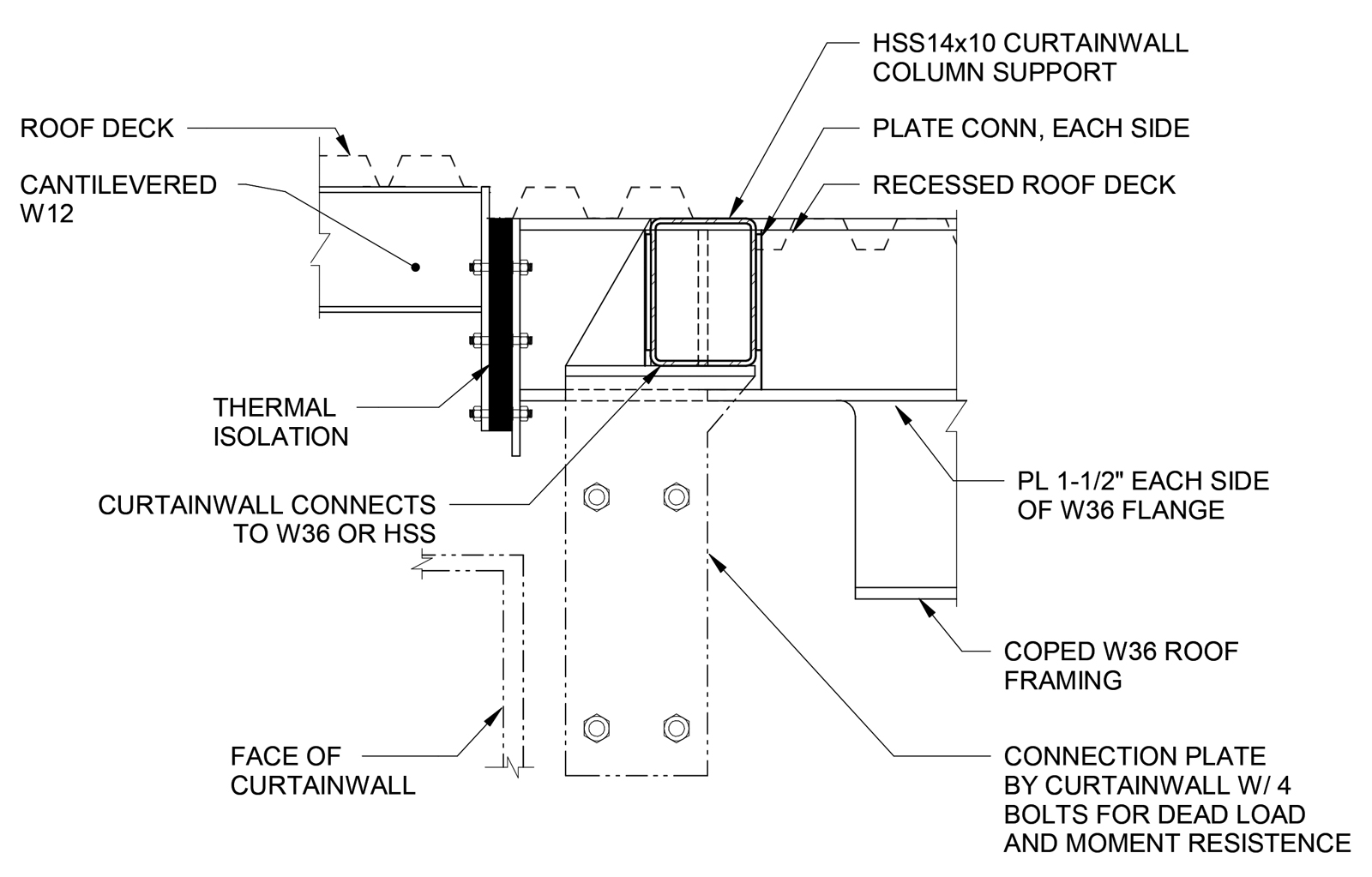

Structure Magazine When Science Becomes Transparent

Girder Slab Typical Sections

In that case, framed beam connections are not suitable, and seated beam connections are preferred In its simplest form, a seated connection is the one in which a horizontal angle with its horizontal leg at its top is used to receive the beam on it, as shown in as per below fig;With regard to your question, there are two connection options that I can think of Detail b4 above provide one of the options A notch on the concrete wall can be made by building a beam pocket on the foundation wall The depth of the beam pocket should meet the minimum bearing length required for the beamMany of our Beam Clamp solutions require a very precise look at loadings and beam configurations FastFit is a preengineered "all purpose" Ibeam connection solution that can be used to connect many different beams of varying sizes and angles

Cmu Wall Connection To Second Floor Stud Walls Architecture Details Wood Beams

Steel Beam Connection Detail On Top Of Masonry Stone Or Brick Load Bearing Wall Youtube

F4 Floor to Load Bearing Wall Connection F5 Floor Bearing on IBeam Connection F6 Lapped Joists F7 Continuous Joist F8 Floors to IBeam Side Connection F9 Joists Supported by Shallow IBeam F10 Joists Supported by Deep IBeam F11 Floor Joists at Interior Bearing Wall F12 Joists Bearing on Foundation at OpeningOne of the questions I am asked most frequently is "Who is responsible for the trussto(fill in the blank) connection?One such example is the trusstowall connection To answer this question, it helps to recognize there are two types of connections a trusstotruss connection and a "trusstoeverythingelseexceptatruss" connectionThe Truss Designer is responsible for the formerBeam to Wall • Solution • bl bbolts near bottom • minimizes effect of shrinkage 43 Slotted hardware • Avoid contact with cementitious materials Connection Serviceability • Beam on Shelf

Steel Timber Composite Beam To Column Connections With Shear Tab Journal Of Structural Engineering Vol 145 No 3

Detallesconstructivos Net Construction Details Cad Blocks

The best way to make small or cramped rooms larger is to remove a wall between adjoining rooms When you replace a loadbearing wall with a loadbearing beam, you create a larger, more useful floor area and give your home a feeling of spaciousnessThen joists or rafters are attached to the wood with standard joist hangers The drilling and bolting required by this method are so impractical that it's worth changing before constructionThe steel Ibeams most often seen on job sites are called W (wide) and S (standard) shapes, depending on the width of the flange Steel beams are designated by shape, depth, and weight For example, a W8x35 beam is a Wshape about 8 in deep and weighing 35 lb per lin ft

Building Guidelines Drawings Section A General Construction Principles Figures 1 10

Figure 4 8 4 Masonry Setback Wall Roof Connection Steel Frame Membrane Roof Masonry Roof

One type nail and charge will fix the top plate to the flange of the steel beam, and another type nail and charge can be used to fix the sole plate to the 'crete floor A good gunnable construction adhesive such as PL 375 can give additional strength to the joint For using the gun, there are a lot of good howto videos on YouTubeCut 2by lumber with a circular saw to match the desired length of the new wall The flange width on standard steel Ibeams varies, so use lumber that is the same width as the bottom flange of theIn such as a case it is called unstiffened seat connection

Solved The Floor Design Of An Industrial Building Calls F Chegg Com

Connection For Beam Very Close To Concrete Wall Engineering Stack Exchange

Steel beam connections without hangers Here's another type of attachment, using a steel beam with wood filler fixed only to the top and bottom flanges It doesn't need a bottom flangebearing hanger as you can cut away the trimmable end of the open joist TRIFORCE ® at an angle, to achieve the supportSteel Connections Dr Seshu Adluri Beam to Column Rigid Joints Stiffener plates are used to 'shore up' the column flanges against the forces transmitted by the beam flanges The stiffeners may be full length or may extend only part of the column web depthFoundation Wall Foundation Beam Column Column Column Beam Slab Stair Slab Wall Wall 14 Mechanical Splices Connection Reinforcing bar t Hybrid Connections BEAM – COLUMN CONNECTION Plan view of the end connection Sectional view of interior connection Courtesy BG Shirke Cross section of

Wide Flange Beam To Hss Column Moment Connections Steel Tube Institute

Steel Beam Reinforced Concrete Wall Simple Connection Youtube

F4 Floor to Load Bearing Wall Connection F5 Floor Bearing on IBeam Connection F6 Lapped Joists F7 Continuous Joist F8 Floors to IBeam Side Connection F9 Joists Supported by Shallow IBeam F10 Joists Supported by Deep IBeam F11 Floor Joists at Interior Bearing Wall F12 Joists Bearing on Foundation at Opening33 Beam to Wall ConnectionsThis will mean removing locally wall plate and taking off 1 or 2 layers of brick My question is how do we fix this beam to masonry so it doesn't rotate I have looked in Simpson catalogue and the only connection that would be suitable is the wall strap (please see attached) The problem is that this only works for new masonry wall

Point Load Beam Column Connection Brick Wall Room Height Lintel Steel Youtube

Solved 1 The U Shaped Beam Is Attached To The Wall At Po Chegg Com

Precast Wall Connections O'Reilly Concrete One 0428T Precast Wall Connection Videos A Typical Foundation layer with an O'Reilly precast wall

Detail Of Steel Beam To Concrete Wall Connection Bolted Seat Steel House Tool Storage Diy Building A House

Revitcity Com Beam Connection To A Concrete Wall

Pre Stressed Wall Panels Products Proform

The Comprehensive Technical Library For Logix Insulated Concrete Forms

Self Centering Steel Timber Hybrid Shear Wall With Slip Friction Dampers Theoretical Analysis And Experimental Investigation Cui The Structural Design Of Tall And Special Buildings Wiley Online Library

Seattle Central Library Curtain Wall Design Lmn Architects

Building Guidelines Drawings Section A General Construction Principles Figures 1 10

How To Determine If A Wall Is Load Bearing Cbs Structural Engineers

Modeling Of Coupling Beams In Shear Walls Perform 3d Computers And Structures Inc Technical Knowledge Base

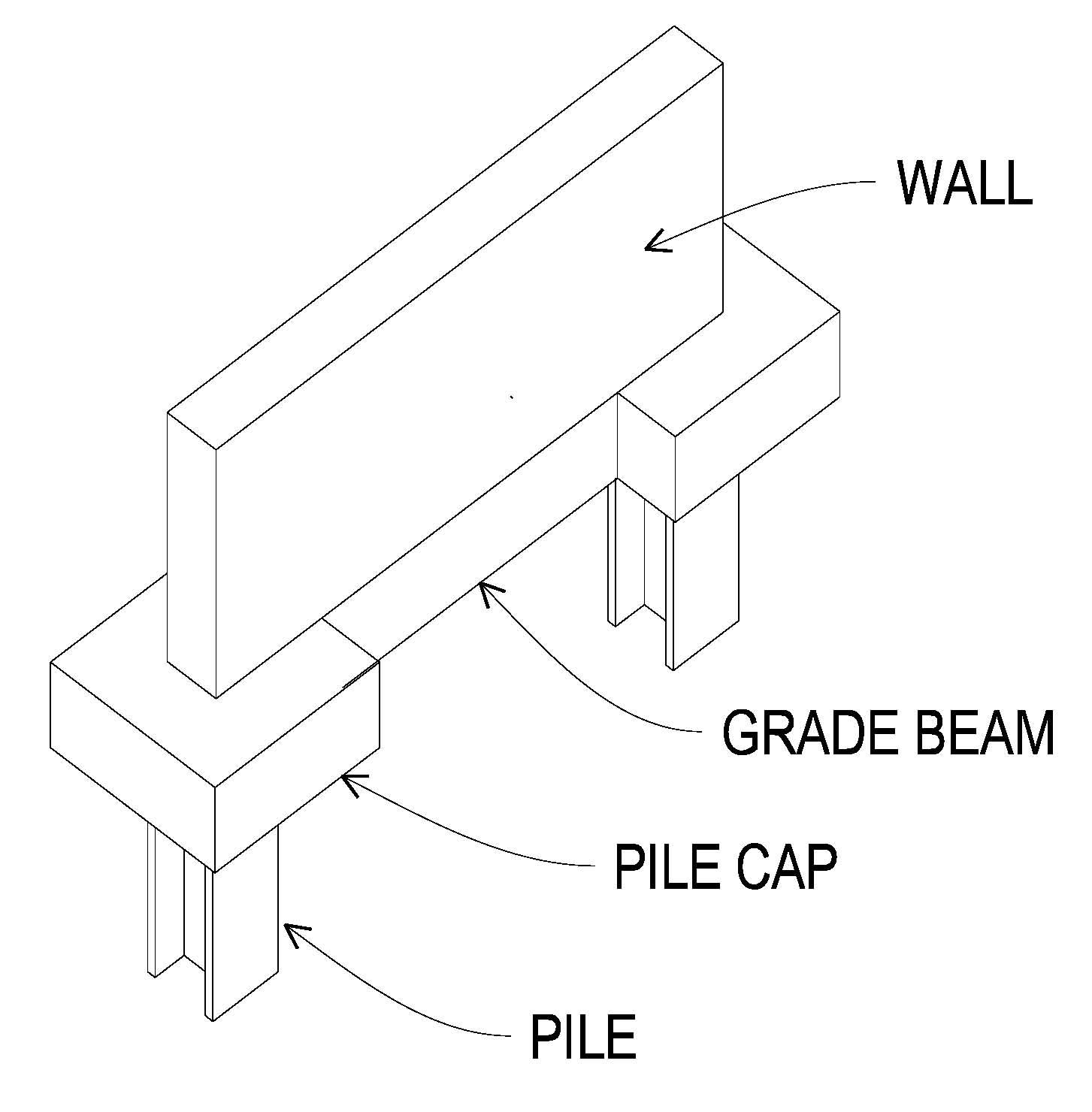

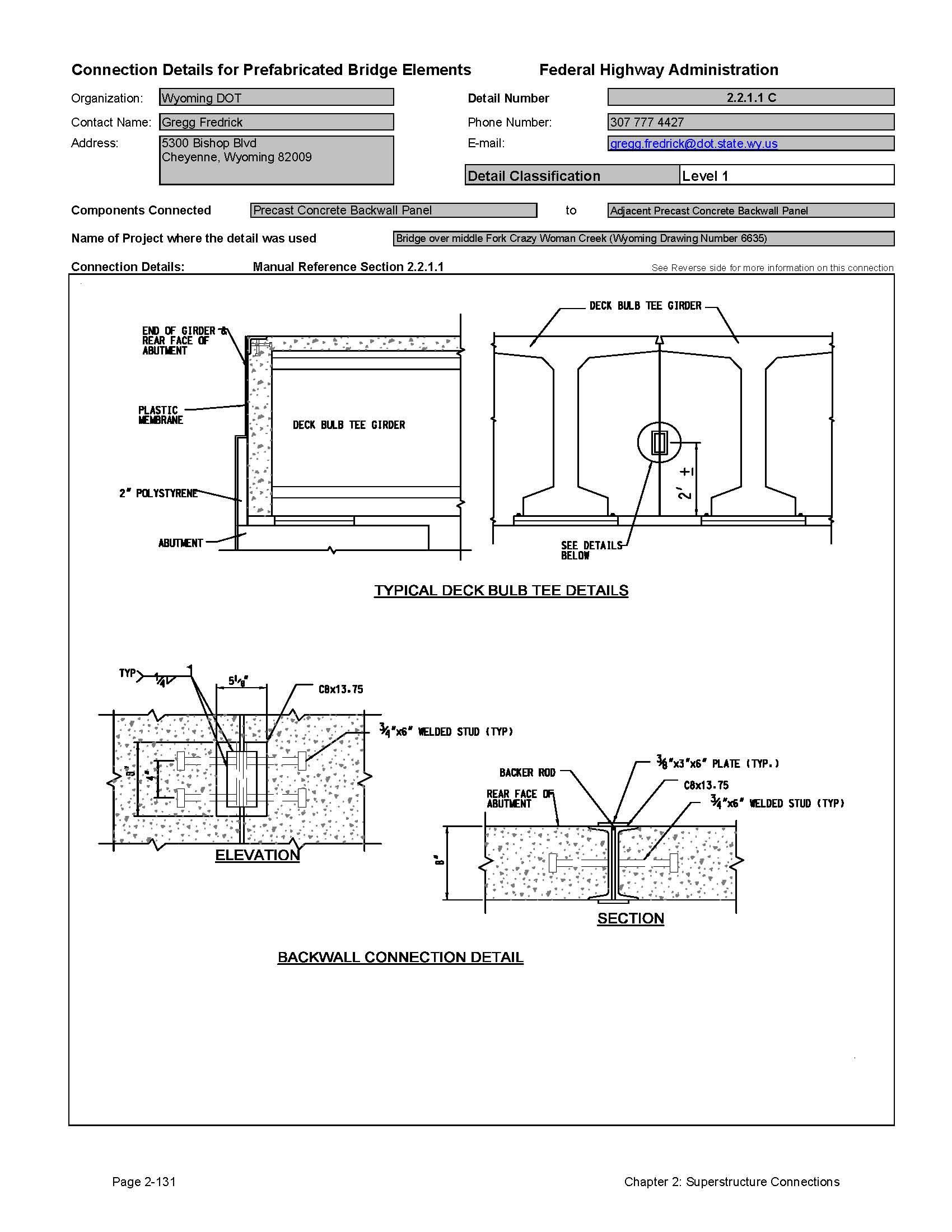

Chapter 3 Substructure Connections Connection Details For Pbes Abc Accelerated Technologies And Innovations Construction Federal Highway Administration

Structural Steel Drawings Computer Aided Drafting Design

Structure Steel To Wood Home Building In Vancouver

The Comprehensive Technical Library For Logix Insulated Concrete Forms

The Comprehensive Technical Library For Logix Insulated Concrete Forms

02 1 0711 Floor Connection Detail Option 1 International Masonry Inst Construction Details Architecture Steel Structure Buildings Metal Building Designs

Stick Framing To Timber Frame Construction Detail Timber Frame Hq Timber Frame Construction Timber Frame Timber Framing

Steel Connections Designer Gable Wall End Plate Graitec

Steel Beam Reinforced Concrete Slab Beam Simple Connection Youtube

Steel Beam To Concrete Wall Connection Design Example Lewisburg District Umc

Structure Steel To Wood Home Building In Vancouver

Wide Flange Beams In Light Frame Construction Simpson Strong Tie Structural Engineering Blog

Sips For Post And Beam Wall And Roof Systems Vermont Timber Works

Structure Steel To Wood Home Building In Vancouver

Revitcity Com Steel Beam Connection With Structural Wall

A Connection Of Rigid Diaphragms To Timber Beams B Connection Of Download Scientific Diagram

Structure Magazine Night Moves On Boylston

Specific Element Intersections And Junctions

Connections Of Steel Beams Dwg Detail For Autocad Designs Cad

Wide Flange Beam To Hss Column Moment Connections Steel Tube Institute

Grade Beam Wikipedia

Cyclic Behavior Of Replaceable Steel Coupling Beams Journal Of Structural Engineering Vol 143 No 2

Structure Steel To Concr Home Building In Vancouver

Structure Magazine When Science Becomes Transparent

Timber Truss End Support On Load Bearing Wall

Solved 2 The U Shaped Beam Is Attached To The Wall At Po Chegg Com

34 Massive Wood Connection From Roof To Wall Scale 1 Download Scientific Diagram

Solved Connecting Steel Beam To Wall Autodesk Community Robot Structural Analysis Products

Revitcity Com Beam Connection To A Concrete Wall

Structure Steel To Concr Home Building In Vancouver

Revitcity Com Steel Beam Connection To Icf Walls

Wood Beam Design And Installation Considerations Weyerhaeuser

Applications Wall Slab Rhino Mechanical Connections

Solved End Plate Connection Of Steel Beam To Concrete Wall Autodesk Community Autocad Structural Detailing

Building A Circular Future By 3xn Gxn Issuu

Steel Beam To Concrete Wall Connection Design Example Lewisburg District Umc

Steel Beam Reinforced Concrete Wall Endplate Moment Connection Youtube

Doctor Who Thirteenth Doctor Time Lord In Training T Shirt In 21 Wood Architecture Timber Structure Roof Detail

Parametric Study Of Exterior Shear Wall Floor Slab Connections Journal Of Performance Of Constructed Facilities Vol 29 No 6

Connection Details Aluminum Canopies Architectural Fabrication

Connection Details Aluminum Canopies Architectural Fabrication

Connections For Timber Concrete Hybrid Building Experimental And Numerical Model Results Journal Of Performance Of Constructed Facilities Vol 30 No 5

Chapter 2 Superstructure Connections Connection Details For Pbes Abc Accelerated Technologies And Innovations Construction Federal Highway Administration

Solved Connecting Steel Beam And Column Using Cap Plate Autodesk Community Revit Products

Connection Details Aluminum Canopies Architectural Fabrication

Lean 2 Beam Lean 3 Beams Manualzz

0 件のコメント:

コメントを投稿